The ultimate aim of every production unit is to minimize the unproductive activities and invest on productive ones. ‘Caffeine’, a software solution developed by Shlok Hariramani, Undergraduate Fashion Technology student from NIFT, New Delhi, as a part of an internship project is a step towards making the processes much simpler by mapping few of the I.E. department activities. Team StitchWorld analyses the high points of the solution.

Planning brings efficiency. This statement would be the least and the most obvious statement to anyone working in the garment industry. The success and failure of a venture can be attributed to the way things are planned and implemented.

For any and every new order that comes in, the first step towards planning begins by sending the sample to the I.E. (Industrial Engineering) department (well if you planned for one) or a Masterjee who will analyze it and look for various intricacies and the operations involved. At the same time he will plan the number of machines required, and design a layout for the sewing line. This will be based on the process and material flow of the sewing floor.

The process begins with creating a separate work record for each order which includes Order number, Style name, Daily target, Daily factory operative time, etc. Using these parameters and the SAM of an operation it calculates the hourly target and suggests the operators (manpower in the picture) required to balance the line and meet that target. The actual allocation of operators and helpers (if required) is however, done by the user with a view of keeping it closer to the suggested labour. The jigs/attachments/folders used are also recorded.

Caffeine also keeps a count of the machines required and summarizes them so that their availability can be planned beforehand. Using this information it automatically generates an operation bulletin clearly stating the total number of machines, operators and the total SAM for each section (of the sewing line) as well as the entire line. It also compares the theoretical manpower with the actual allocation done.

Planning trims and accessories consumption are easier, but to quantify the thread consumption requires many man-hours of a person of experience and wisdom. However, even after working out the consumption it would still require constant updating as the order progresses.

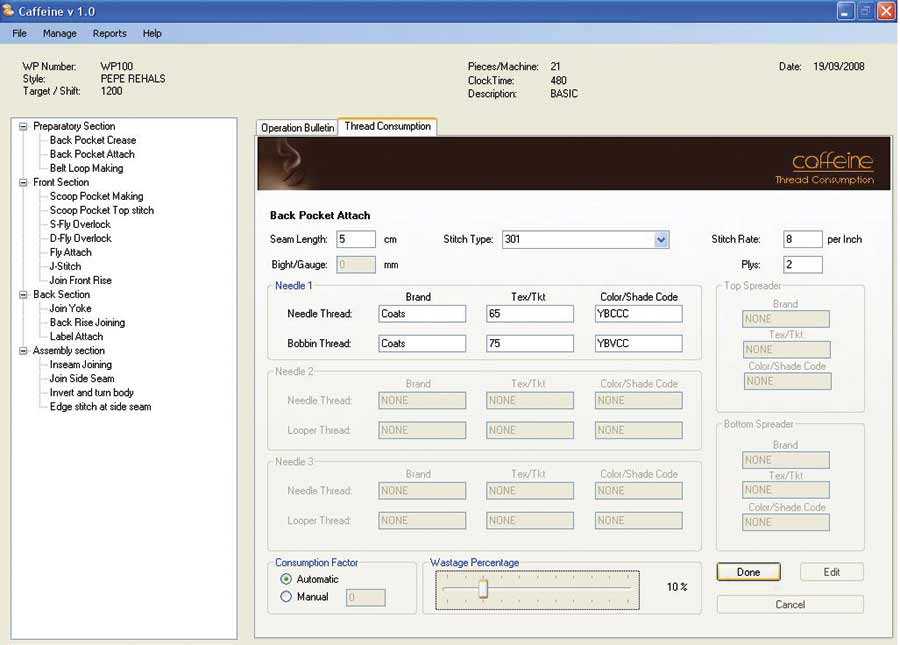

Caffeine uses the Operation pane (created using Operation breakdown process) to calculate operation-wise thread consumption just by specifying a few parameters on Stitch type, Bight (if applicable), SPI, Number of fabric layers and Seam length, Thread brand, Colour and Ticket number/TeX.

It then generates a thread consumption report which explicitly specifies thread required by each operation and thread summary stating the overall requirement/ordering quantity of each thread.

The software thus, reduces the repetition of the common work for all these activities as well as eliminates many of the inefficient manual steps which can be automated.

The software additionally creates a Line Layout which can be modified and changed according to the needs of the sewing line. The machine stickers stating the name of machine, operation and the hourly target along with the SAM value are also automatically generated.

While the aim of the software is quite similar to any other production planning software, there are many features which differentiate it from the software solutions offered by branded thread manufacturers such as –

1. Eliminating the tedious job of copying the same data for different purposes. 2. Converging various activities on a single common platform. 3. Limiting the skills of the I.E. person only to qualitative data entry level (non-repetitive); all the other jobs would be automated. 4. Increasing the efficiency and hence reducing the time required for planning.

Leading thread suppliers provide their thread consumption software for free but they perform well when used to calculate thread packages and cones provided by the same company. The brand name of thread and the package sizes in which they come are fixed and non-editable whereas Caffeine is flexible. Any and every brand of thread without any constraint on the minimum package size can be easily worked with.

In case of double needle stitches where there are 4 threads packages, the option for individually specifying all of them is rare. Such softwares usually talk about threads in terms of top thread and bottom. Hence, if there are two different top threads or bottom threads, one will have to break the operation into two single needle stitch operation. Caffeine on the other hand allows explicitly specifying as many as 8 different threads in a single operation. It also allows differential wastage percentage specification for each operation, unlike other branded solutions.

Like every other thread consumption software Caffeine calculates the thread consumption based on the standard consumption factors. However unlike them, it allows user to specify manual consumption factor if they believe that the standard factors don’t apply to his/her factory. At the same time this option creates a scope of calculating thread requirements even for those hypothetical machines/stitch types which are yet to be invented and whos consumption factors are not known.

While the initial version of the software is released, there are many more features which are presently being worked for the advanced version. SAM determination for example, is a critical process for correct target setting. Checking whether the SAM entered for a particular operation is correct can be desirable for some, who would like software intervention in the process, but those who would like to put their experience to might not use it. Hence, a second version is already in process, which would incorporate features like suggesting approximate SAM values for different product categories. Templates for operation breakdown of some basic as well as few common variations are planned to be incorporated. Machine inventory maintenance record keeping would also enhance the shop floor planning.

Leave a Reply